Plant 15 000 in during the design phase offered to the Investor in Ukraine.

Design of the technology – technical aspects of the purification process operating within the flow system, compatible with RP patent No 197513, with a capacity of 15000 [m³/d]

The technological process is based on the biological reactor cycle using activated sludge in the form of flocculent dispersible suspension and settled biomass (immobilised) on submerged flow deposits.

The process takes place with the sewage flow through following units of operations of the purification process. The whole treatment plant is located in the building.

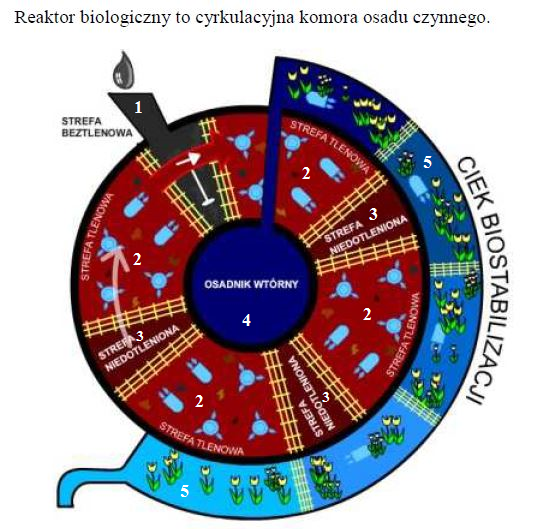

The biological reactor is circulating the change of active sediment.

- Anaerobic zone

- Aerobic zone

- Anoxic zone

- Secondary settling tank

- Bio-stabilisation watercourse

The schema of the biological wastewater treatment plant, with biological removal of biogens, in which two types of organisms are involved in the process (the dispersed sludge and the settled sludge), purifying the waste water for purity corresponding to class II regarding the purificatin level, and energy intensity 0,3 – 0,5 [kWh/m³].

Schemat technologiczny – blokowy

- sewage pipe

- Inflow point

- Pomping station

- Sand

- Sieve grit with sand filter

- The BT Chamber (anaerobic)

- Screens

- Circular reactor

- Secondary settling tank

- Wastewater thickener

- Presses

- Dehydrated sludge

- Bio-stabilisation watercourse

- The air

- The receiver - artificial river

Sawage treatment plant Qdav = 15000 [m³/d], Qdmax = 18000 [m³/d]

Qhśr = 625 [m³/h] = 173,61 [l/s] , Qhmax = 2,5 x Qhśr = 1562 [m³/h] = 434 [l/s]

1. Secondary cylindrical sludge tank

The load of the the secondary tank = 0,5 [m³/m².h]

Dow = 36 m, how = 5,0 m, Vow = 5087 m³, czas zatrzymania w OW

T = (1,525 ÷ 2,36) x (Q)1/2/u; T=1,525 x 0,4167/0,42 = 1,51 do 2,36 x 0,6588/0,42 = 3,70 h

T = VOW:Qh ; T=5087/625 = 8,14 h, do 6087/1560= 3,25 h

2. The BT Chamber + BR (BT – anaerobic , BR – Bio-reactor)

VBT = 2125 m³, DBT = 24 m, hBT = 5,0 m

3. Bio-reactor – the capacity

Vbr = 16170; Aerobic zone, VT = 10780 m³, anoxia zone, VNT = 5390 m³,

Both zones are located in the tire of the diameter:

– interior Dwew = 36,4 m,

– exterior Dzew = 70,4 m,

Tyre width 17 m. In case of applying six anoxia zones, there is a necessity to mount 3060 structures 1m x 1m.

4. Wastewater thickener

Vzag = 1000 m³, Dzag = 16 m, hzag = 5,0 m; submersible pump in the thickener ; lifting up to 10 m, the efficiency 400 [l/min]

5. Dmuchawy

2×640 [Nm³/min] lub 4x 320 [Nm³/min]; Δp = 0,6 bara

6. Sitopiaskownik with a capacity of 600 [l/s]

7. Pompa w pompowni i komorze BT;

zatapialna, lifting up to 10 m sł. wody, wydajność = 600 [l/s], cztery sztuki

8. Pompa wolnostojąca cyrkulująca osad zawracany i nadmierny;

lifting up to 10 m sł. wody, wydajność = 600 [l/s]

9. Zgarniacz denno-powierzchniowy do zbiornika cylindrycznego DN = 36 m,

korzystnie FinnChain

10. System dekantacyjny ATWAX w zagęstniku

11. Prasa filtracyjna

o wydajności [400 – 500 m³/d] osadu o zawartości suchej masy do 2% wagi

12. CB (Ciek Biostabilizacyjny)

– 232 m cieku 2m głębokości, 3m szerokości w dwóch kanałach opasujących BR,

każdy długości 116 i 116 m, Objętość łączna 1392 m³.

The investment includes the implementation of project based on::

1. Architectural-construction part - tanks and the building

2. Technically- technological part

3. The transit road part

4. Electrical part and PiA